Aerospace Fittings

Davis Machine has specialized in the manufacture of high tolerance, turn heavy and complicated geometry fittings since our founding in 1953. From a simple tight tolerance bushing to multiple compound angles with intricate ID / OD requirements made from difficult to machine material, we have the team and process to deliver.

Our fittings division works the right part on the right equipment. We have a division of multi-function equipment to “drop off” simple to complicated linear parts in a single operation. In addition, we operate precision lathe and mill machines when the part geometry / material / quantity simply demands multiple operations and dedicated fixturing.

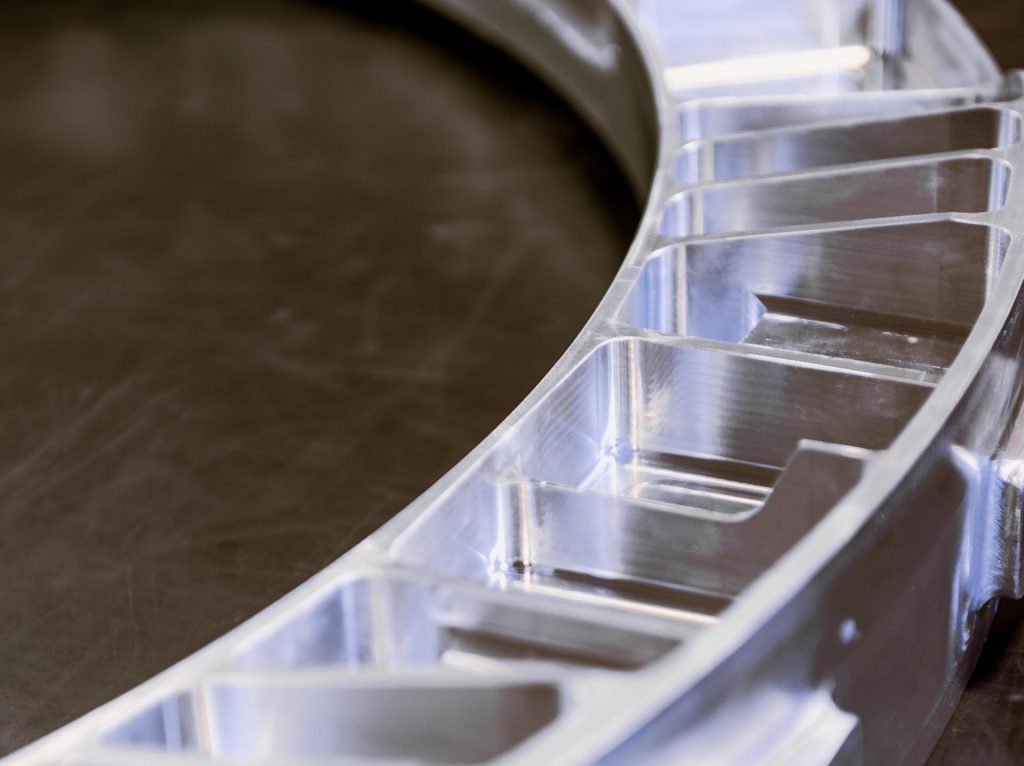

Aerospace Structural Components

In 2018 Davis Machine entered the Aerospace Structural Components market. Our team has been assembled from around the region based on expertise in the unique engineering, manufacturing and quality requirements of mid to large format structural components. Our team and equipment are capable of quickly processing new product through first article and into delivery.

Our structures division standard components are titanium or aluminum “hog outs” with a strong track record of success in casting conversion, thin wall monolithic components and assembly heavy components. Our team is familiar with working with model-based, print-based and even hard tool defined components on development and inspection.

Aerospace Assemblies

Many OEMs have decided their core competence is not assembly of minor components. Therefore, Davis Machine built a team capable of combining in-house manufactured goods with sourced items to deliver install-ready assemblies.

Our team is continually growing its capability and complimentary support tooling in this area. Familiarity with the basics of riveting, press-fit and shrink-fit bushing installation, bearing staking, nutplate and bracket bonding plus associated sealing, touch up activities and more is high. Comfort with taking on assemblies of increasing complication either by quantity (supply chain critical) or by design (assembly process critical) is something we work through transparently with each customer and project.

Ancillary Services

Our core business activity is the manufacture of aerospace components; however, our mission is delivering the quality and service that the aerospace industry deserves. For this reason, our capabilities (in total or in part) are always available to our customers.

The Davis team has supported customers with design manufacturability studies, 3rd party inspection, digitization of paper-based designs, inventory optimization models and related financing, manufacturing operation acquisition, partnering on industry standardization with engineering / registrar bodies and much more. In the end, our skills and knowledge are made available to our customers in any way that supports their success.